Not JUST a Machine Shop

40+ Years in Business

AS9100D Certified

Smart Machining Approach

Qualified Expertise

Decades of producing and delivering quality, precision-grade components

We understand just how expensive a faulty part can be to your business operations. Whether you work in oil & gas, aerospace, or any other industrial field, your success revolves around your equipment or part functioning as expected for as long as it can.

Non-conformance represents an insidious market force that costs money and wastes time.

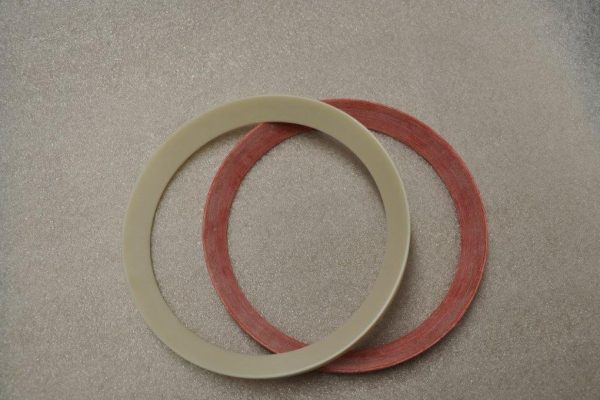

That’s why we’ve spent more than 40 years establishing ourselves as a leader in smart machining of both metal and composite materials.

Get Started

Let’s discuss your project today so we can get started.

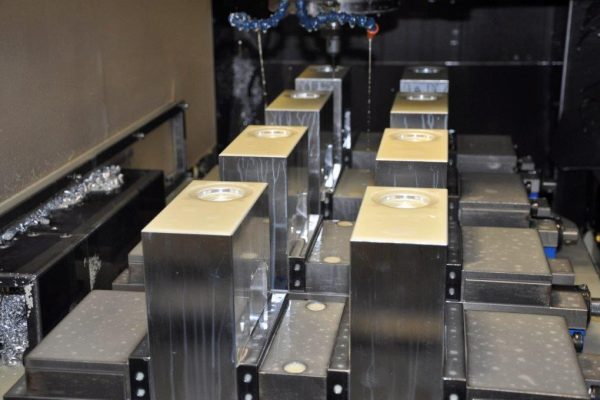

With 25 machining centers, we’re equipped to evaluate your designs, test them, and produce the components you need based on your budget and on a reliable schedule. We’re here to provide the solution, quality, and precision your project requires.

All it takes is a discussion. We’ll take a look at what you need, determine the timelines for production, and partner with you to ensure you have the conforming components you need.

Who We Are

At Hydraulics International, we know you need the best conforming parts—on time and on budget, without compromising quality. But finding a full-service machine shop that can consistently balance all those factors is challenging, particularly when it comes to composite materials.

With over 40 years machining both metal and composite parts, we get it. This is why we’re AS9100D certified and have invested in both the team and the equipment to provide the conforming components you need when failure is not an option.

When you work with Hydraulics International, we help you identify and resolve issues early on with an innovative mindset, secure the required materials, and ensure delivery of the parts you need when you need them.

Get in touch today so you can stop worrying about the expense and headache of components that don’t fit (or worse, fail) and instead save money, deliver predictable integration outcomes, and ensure a reliable product for users.

Who We Are

At Hydraulics International, we know you need the best conforming parts—on time and on budget, without compromising quality. But finding a full-service machine shop that can consistently balance all those factors is challenging, particularly when it comes to composite materials.

With over 40 years machining both metal and composite parts, we get it. This is why we’re AS9100D certified and have invested in both the team and the equipment to provide the conforming components you need when failure is not an option.

When you work with Hydraulics International, we help you identify and resolve issues early on with an innovative mindset, secure the required materials, and ensure delivery of the parts you need when you need them.

Get in touch today so you can stop worrying about the expense and headache of components that don’t fit (or worse, fail) and instead save money, deliver predictable integration outcomes, and ensure a reliable product for users.

What is Smart Machining?

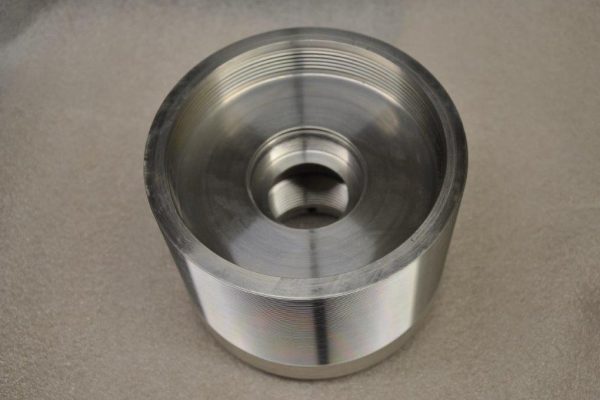

Smart machining is not just “measuring twice and cutting once.” It’s a better process designed to optimize the part you’re getting. It’s a business philosophy that aims to look at the bigger picture and avoid unexpected hurdles before they ever happen. It’s what you can expect when you choose Hydraulics International.

An Integral Qualification

It all starts with client design where we double and triple check a part’s engineering to head off any issues before they become problems. That way your part performs the way you need it.

An Innovative Mindset

Our process embraces a range of material options, different tooling approaches, and an array of machining methods to make sure you get the best part—not just the first part!

Comprehensive Supply Chain

We’re your partner from assembly and integration all the way to supply-chain management and helping manage other outside services like plating, anodizing, and high-temp treatments.

Our Equipment — Your Solutions

Key Equipment

- FARO Inspection Arm

- Romer Inspection Arm

- HE&M automatic saw

- HE&M automatic saw

- Doosan HPS100 Pallet Changer w/full 4-axis mill

- Hass VMC 750 SS 5 axis mill

- Mori Seiki NL2500SY sub spindle live tooling lathe

- Brother SPEED10 M140X1 mill

- Haas VF2YT Vertical w/210mm 4th axis mill

- Doosan DNM 350/5AX 4+1 mill

- Okuma LU3000 EX live tooling lathe

- Doosan 400MB tooling robot gantry lathe

- Mori Seiki NLX2500 sub spindle live tooling lathe

- Daewoo 300C Lathe

- Doosan 2600L lathe

- Mori Seiki NL2500MB/1250 w/steady rest lathe

- Doosan DNM650 Vertical w/320mm 4th axis mill

- Doosan 240MB GL live tooling robot gantry lathe

- Hardinge XP3 1000 vertical pallet changer/mill

- Mori Seiki NL2000SY sub spindle LNS bar feeder lathe

- Daewoo 300C Lathe

- Hass VF3 vertical w/210mm 4th axis mill

- Haas UMC-750SS 5 Axis Mill

- Doosan Dnm 6700 Vertical Machining Center

- LU3000EX MY-600 Lathe

- HAAI VF3 Machining Center

- LU3000-EX-2SC-600

- HAAS UMC-1000SS 5 Axis Mill

- Robotic Extensions – Production Automation